- Product name:Synchronizer intermediate ring

- Product number:

- Views: 755

Products

Contact Us

Add:52 Hanjiang Road ,New Hi-Tech District Changzhou,Jiangsu,China

Tel:(86)0519-85158888

(86)0519-86808888

Fax:(86)0519-85150888

Email:sales@nrb.com.cn

Main structural types

As an individual part, the synchronizer middle ring is an important component of the synchronizer in the automobile gearbox. It matches with the inner ring and outer ring in the synchronizer components. When the inner conical surface of the synchronizer ring contact the outer conical surface of the gear ring that is to be engaged, under the action of friction torque, the two surfaces rotate simultaneously. The relative rotating speed of the gear to the synchronizer ring is zero. Then the gear further joints with the gear ring of the gear to be engaged, completing the gear shifting. According to the designed functional requirements of the synchronizer, there are two main structural types of the synchronizer middle ring.

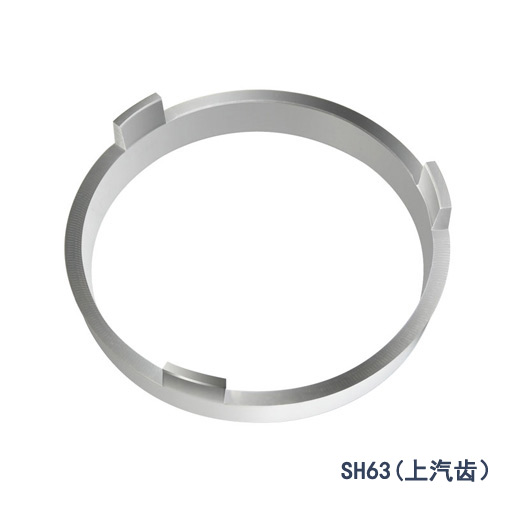

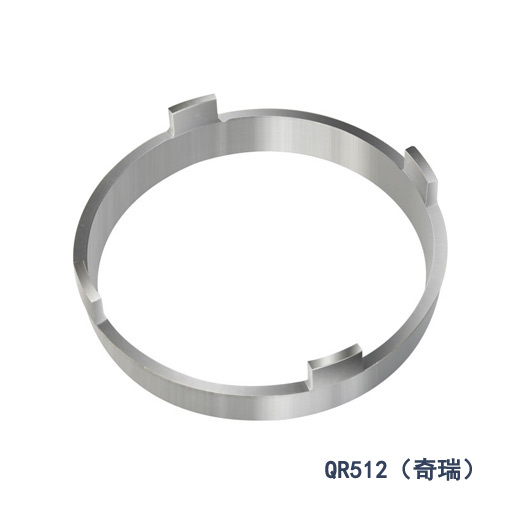

Middle ring with vertical claws

A middle ring with vertical claws is composed of a conical-surfaced body and several raised claws standing vertically on the conical-surfaced body. According to the designed functional requirements of the synchronizer, the vertical-claw middle rings mainly include middle ring with three vertical claws, middle ring with four vertical claws and middle ring with five vertical claws.

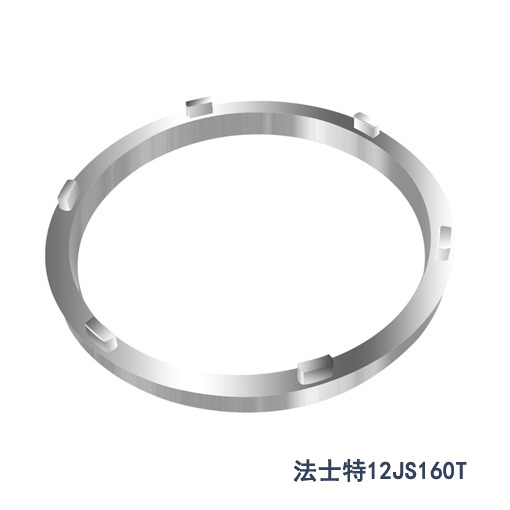

Middle ring with horizontal claws

A middle ring with horizontal claws is composed of a conical-surfaced body and several raised claws on the same plane of the conical-surfaced body.

Main parameters and tolerances

① The claw position of the synchronizer middle ring: ≦0.2mm, the root fillet of the claw R: 0.4-0.8

② The scatter differences of the dimensions of different batches of inner and outer conical surfaces of

the synchronizer middle ring must be within 0.02mm

③ The hardness of finished synchronizer must be within HRC58-63.

④ The effective contact area between the inner and outer surfaces of the synchronizer middle ring

must be equal or greater than 80%.

Material

Most of the middle ring products manufactured overseas use carburizing steel as material. Our company uses mature GCr15 to produce middle rings. By a number of bench tests and market use verification, this material can fully reach to its operation performance.

Key words :

download attachments :

-

1

-

2

-

3

-

产品名称: Needle Roller and Roller

-

-

4

-

产品名称: Shaft Sleeve

-